Product Engineering

We help our customers realize and accelerate their product development goals by creating innovative chip-to-cloud solutions built on our capabilities across the technology stack. Our teams in Storage and ISV are proud to have worked on category-leading products with some of the most demanding use cases. At our core is creating an impact and developing sophisticated products addressing the world’s needs in the areas of Medical Devices and Healthcare, Industrial Products, and Heavy Machinery and Automotive.

Services

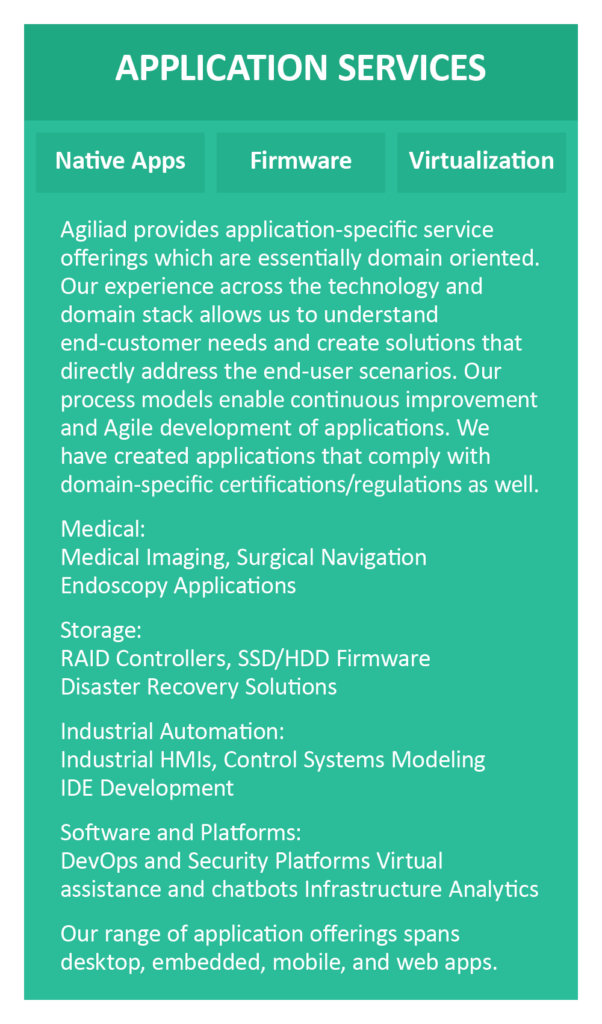

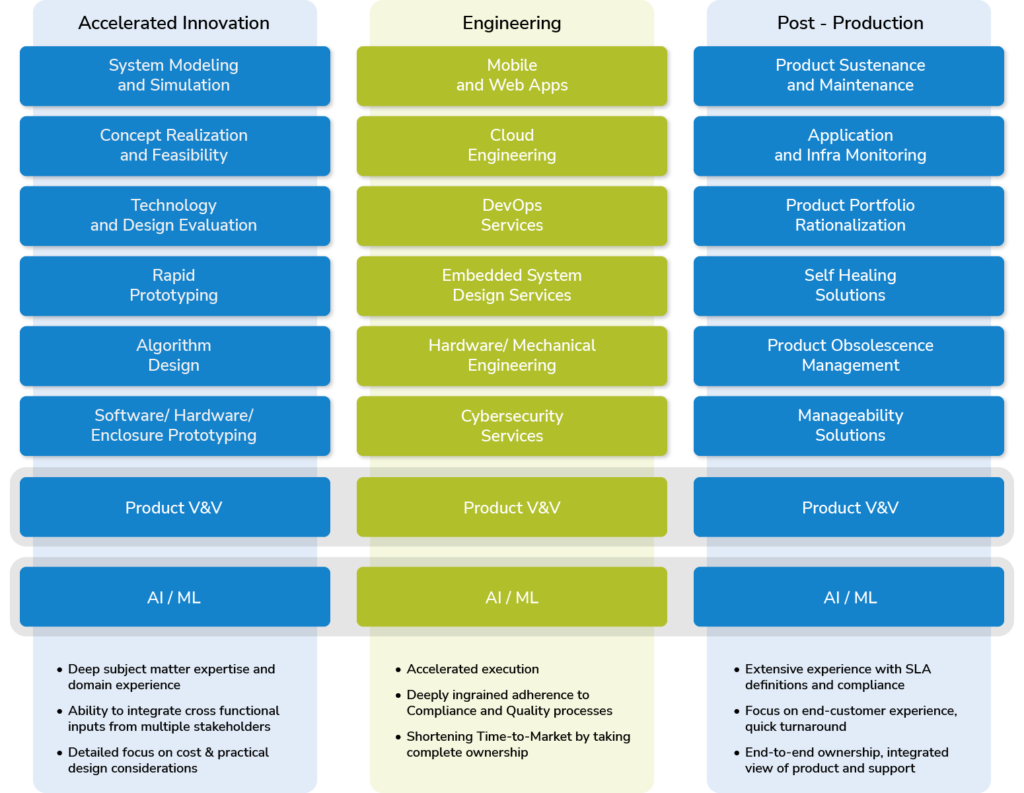

As part of our Services, we strive to deliver exceptional value to our customers by offering a comprehensive range of solutions. Our expertise in Accelerated Innovation, Engineering, Post-production, Artificial Intelligence, and Verification/Validation empowers us to transform ideas into tangible realities. We are dedicated to partnering with our clients to develop cutting-edge products and services that meet the evolving demands of the world. Together, we shape a brighter future through innovation and excellence.

Industrial Products and Heavy Machinery

Helping Industrial Products and Heavy Machinery customers steer through the challenges of the Industry 4.0 driven digital product roadmap

Storage and Cloud Engineering

Engineering the next-generation enterprise software stacks for Data Centers and Cloud Platform Innovators

Medical Devices and Healthcare

Accelerating the development and realization of the regulated medical devices of the future and enabling better clinical outcomes

Software Product Engineering

Building and modernizing software products with a focus on transformation through automation, data processing, DevOps

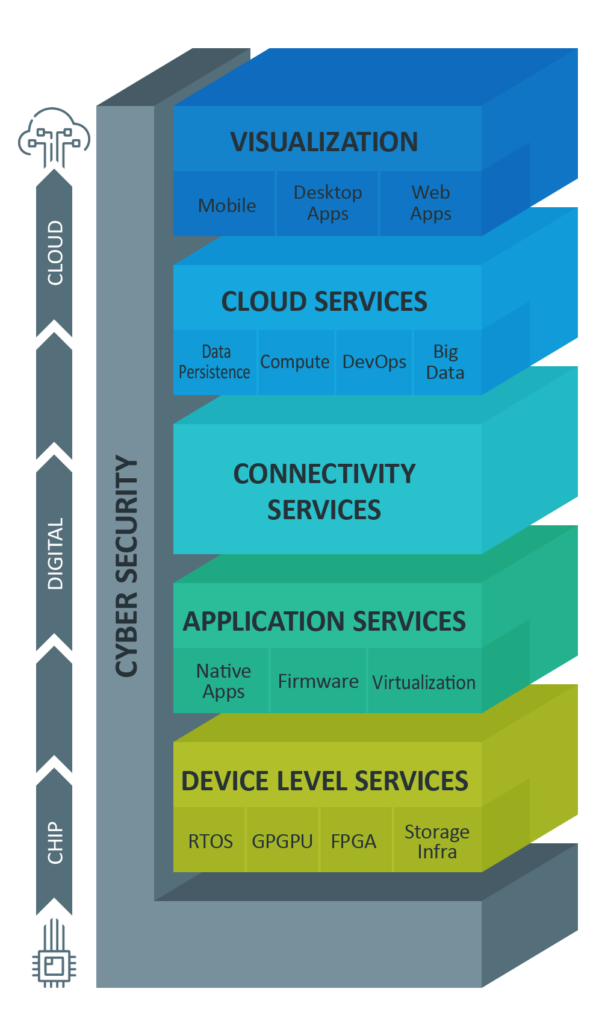

Capabilities across the Technology Stack

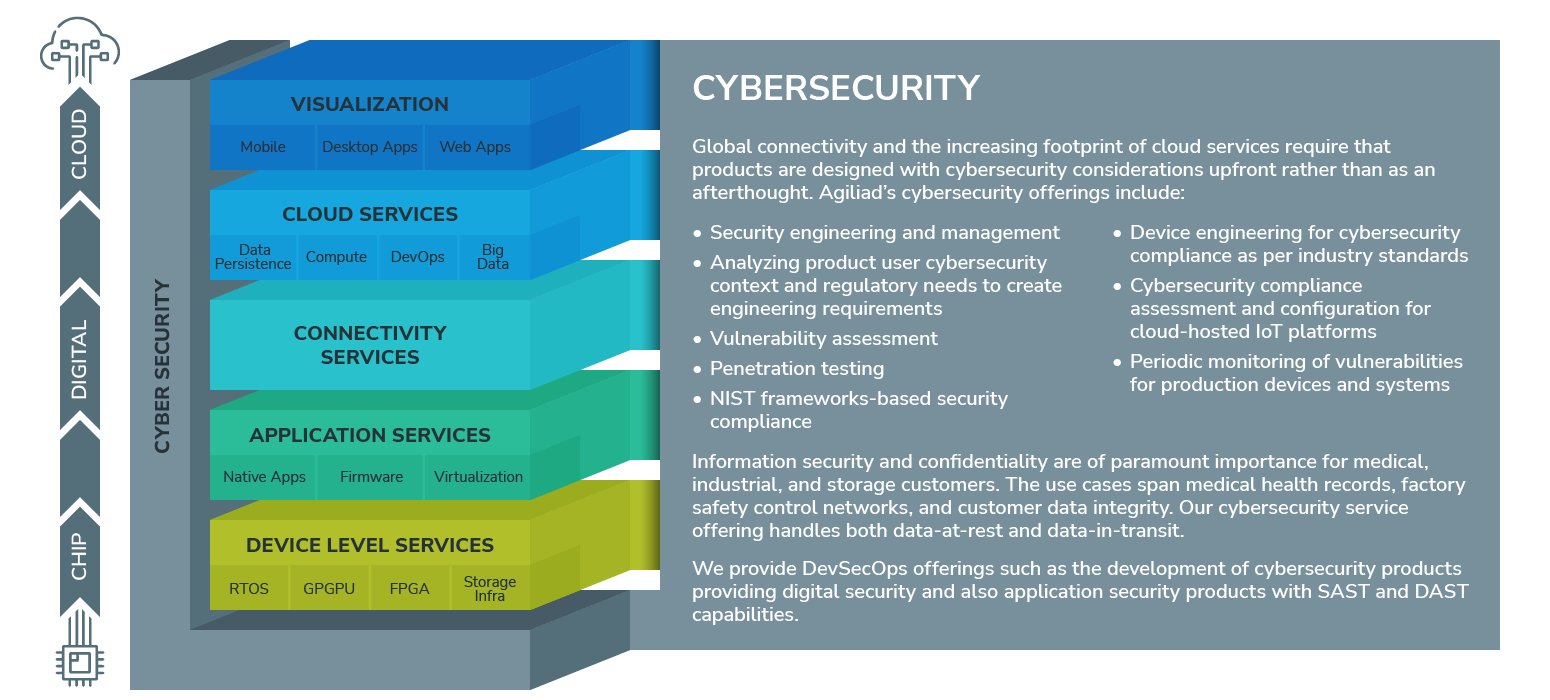

Cybersecurity

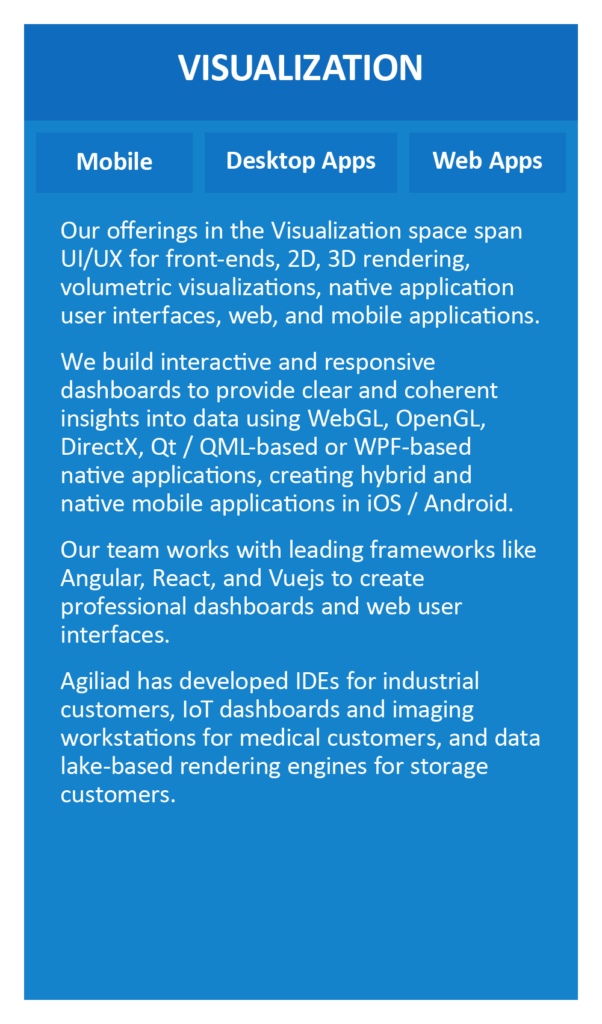

Visualization

Mobile

Desktop Apps

Cloud Apps

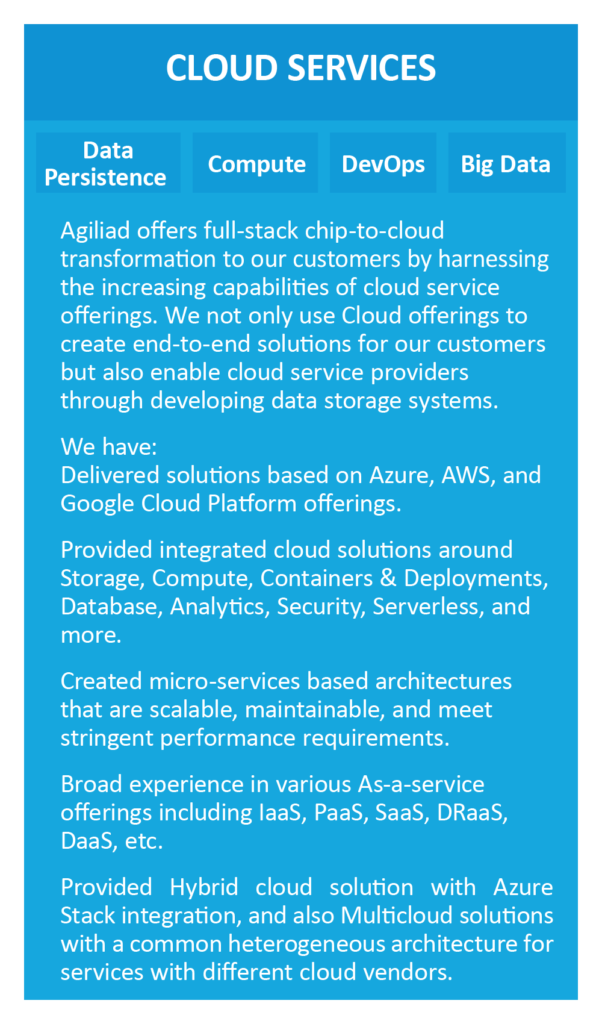

Cloud Services

Data persistence

Containers Microservices

Big Data

Connectivity Services

Application & Firmware Offerings

Device Level Services

HW Layer Chip Layer

GPGPU/FPGA

Storage Infra

Cybersecurity

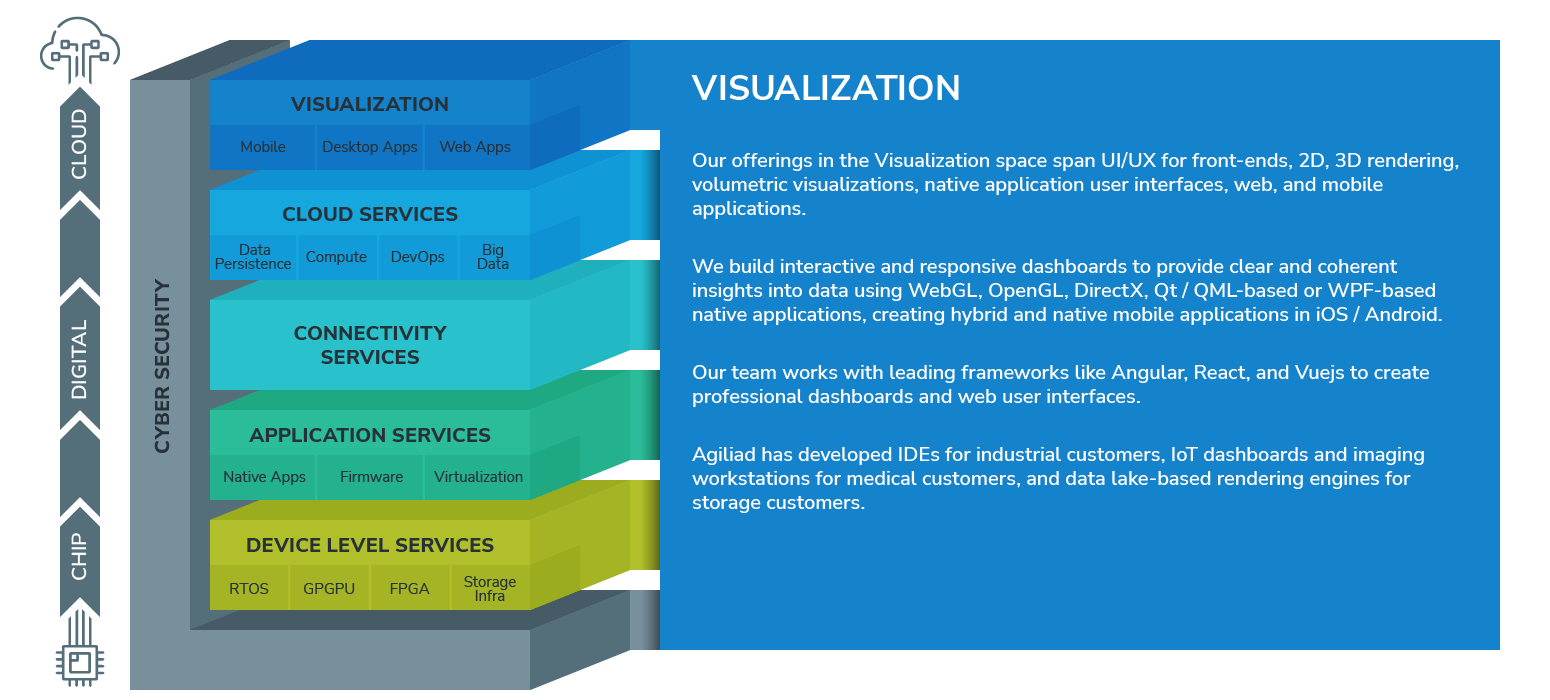

Visualization

We have been working for a number of customers for Building Interactive and Responsive Dashboards for providing clear and coherent insights into data.

Our capabilities in this space range from developing Qt / QML based or WPF based native applications to creating hybrid and native mobile application in iOS / Android apps. Our team has experience of working on all leading frameworks like Angular, React, Vuejs to create professional dashboards and web user interfaces.

We have developed IDEs for industrial customers, IoT dashboards for medical customers, data lake based rendering engines for storage customers.

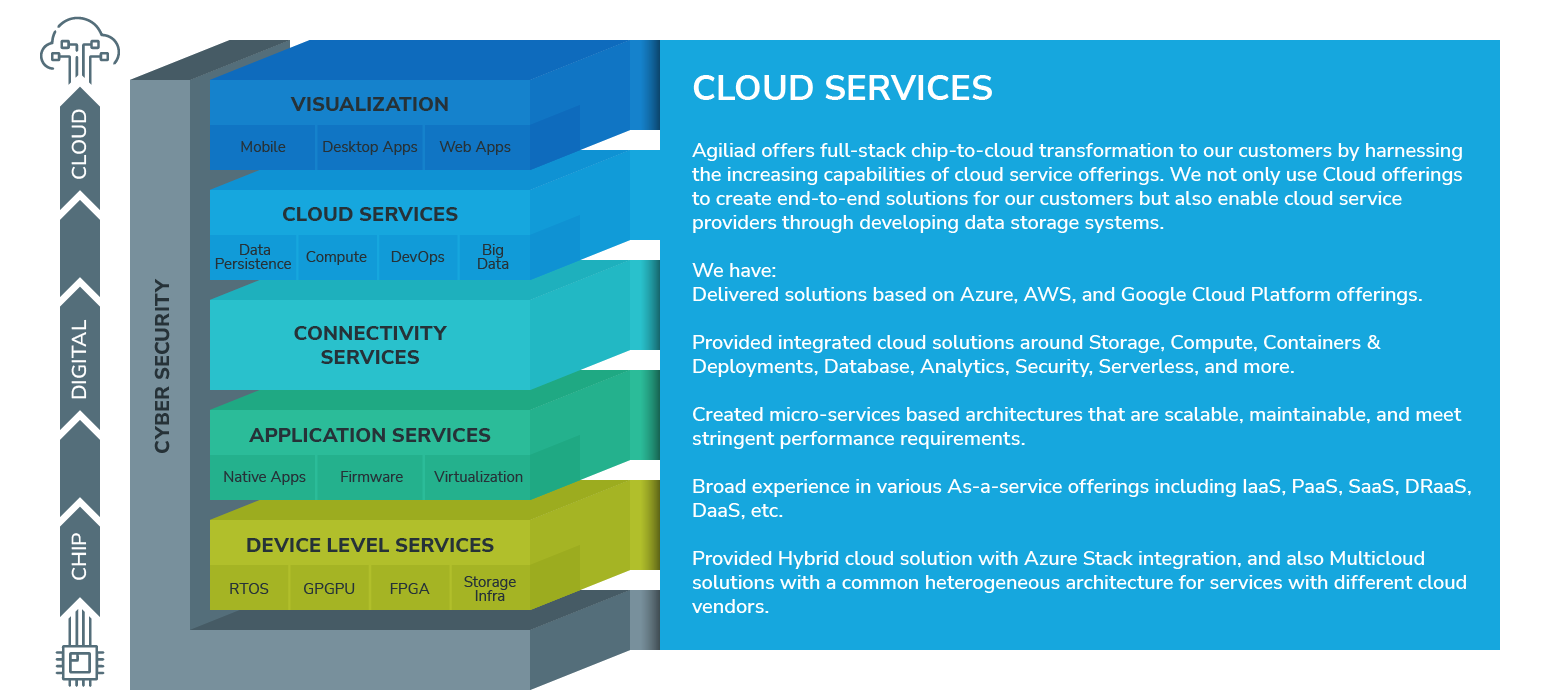

Cloud Services

We have delivered solutions to customers that are based on Azure, AWS, Google Cloud Platform & Alibaba cloud offerings and provided integrated solutions based on SQL, No-SQL, Blog storage, Big Data storage, Time Series databases for our customers.

We have experience in creating micro-services based architectures that are scalable, maintainable, meet stringent performance requirements and have implemented a number of projects that utilize the docker, Kubernetes infrastructure.

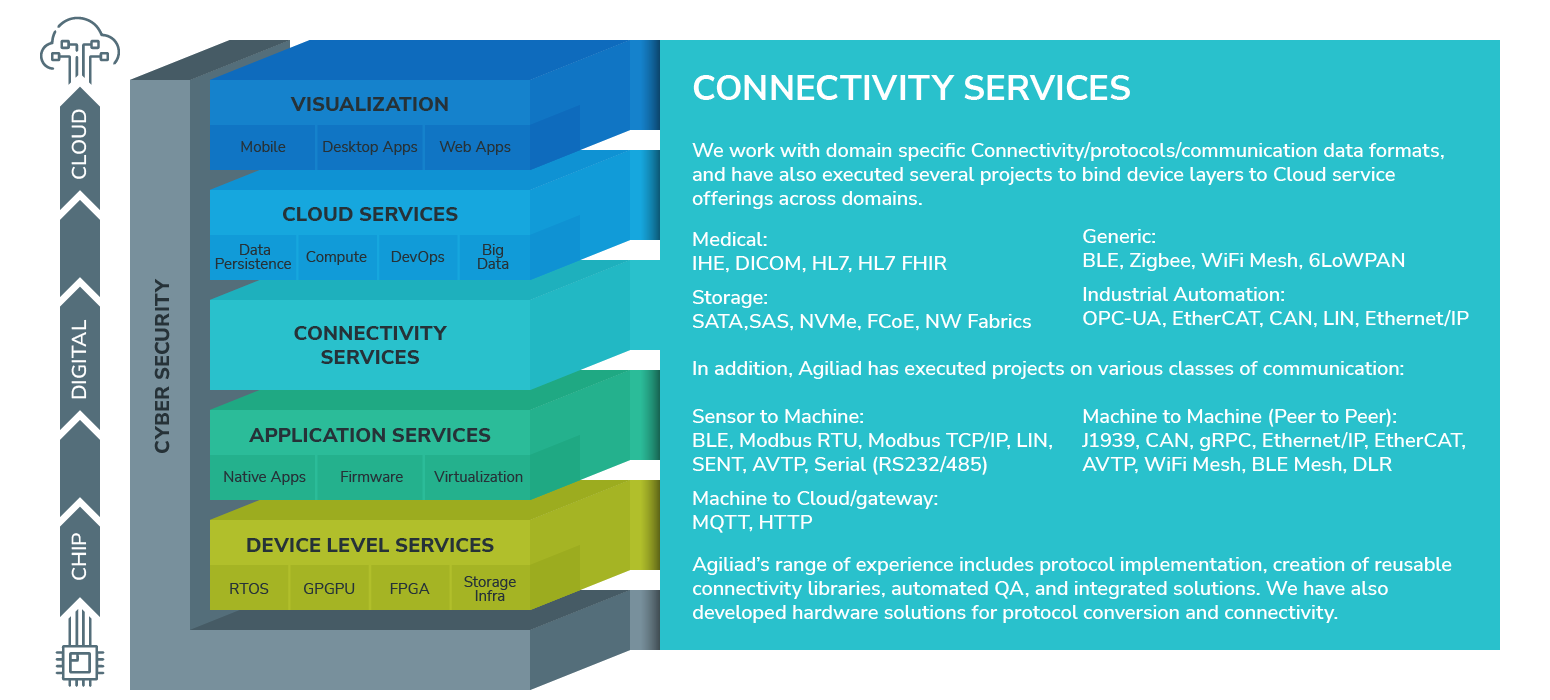

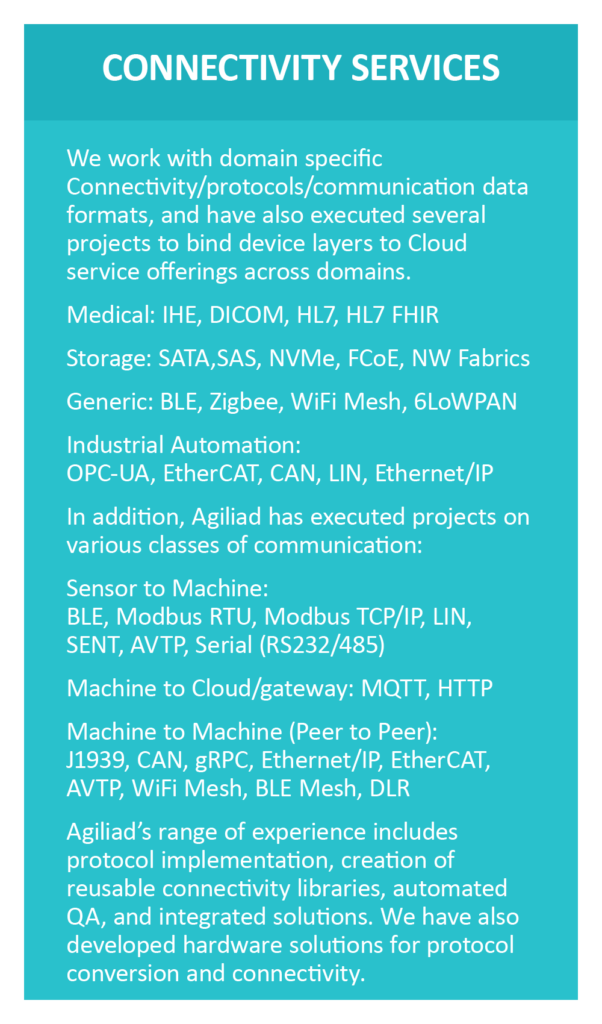

Connectivity Services

Connectivity / protocols / communication data formats are predominantly domain specific without overlapping specifications.

NW Fabrics

Ethernet/IP

6LoWPAN

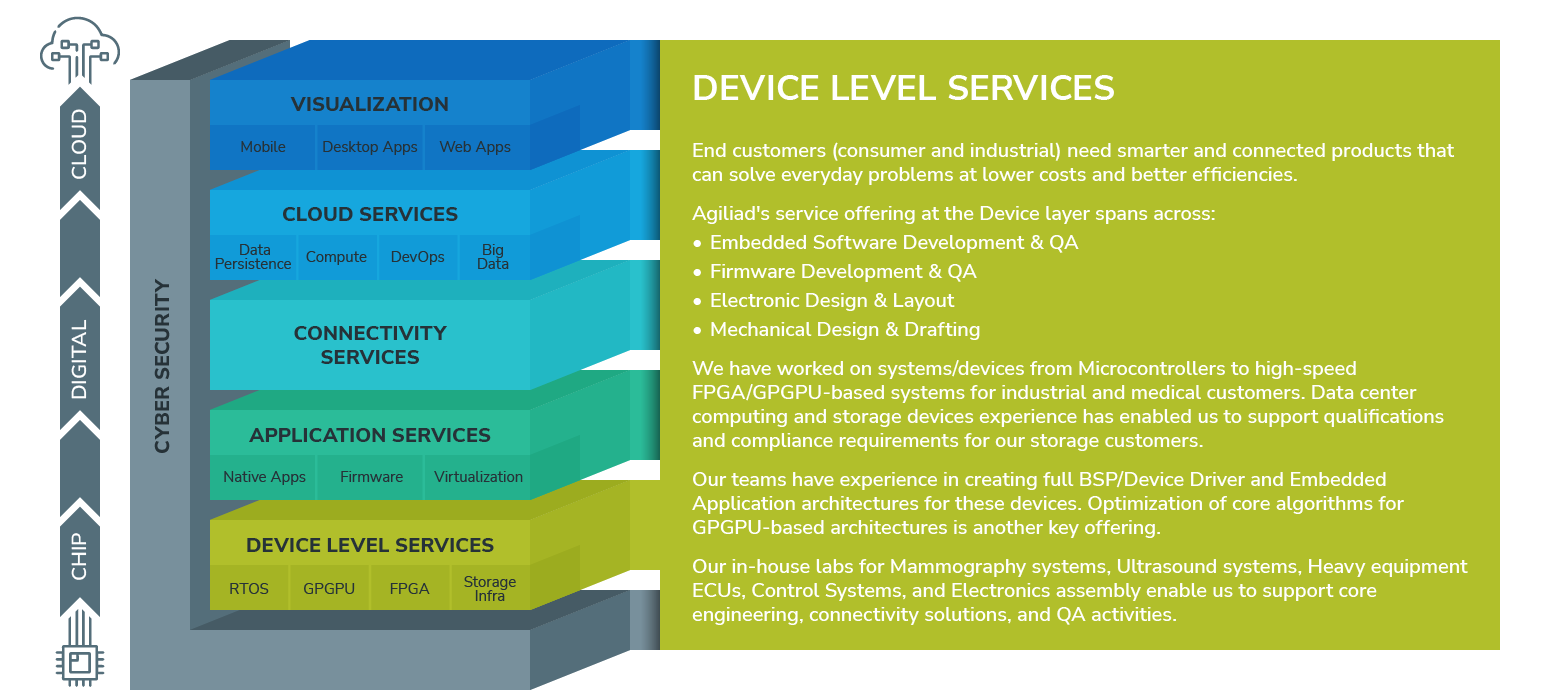

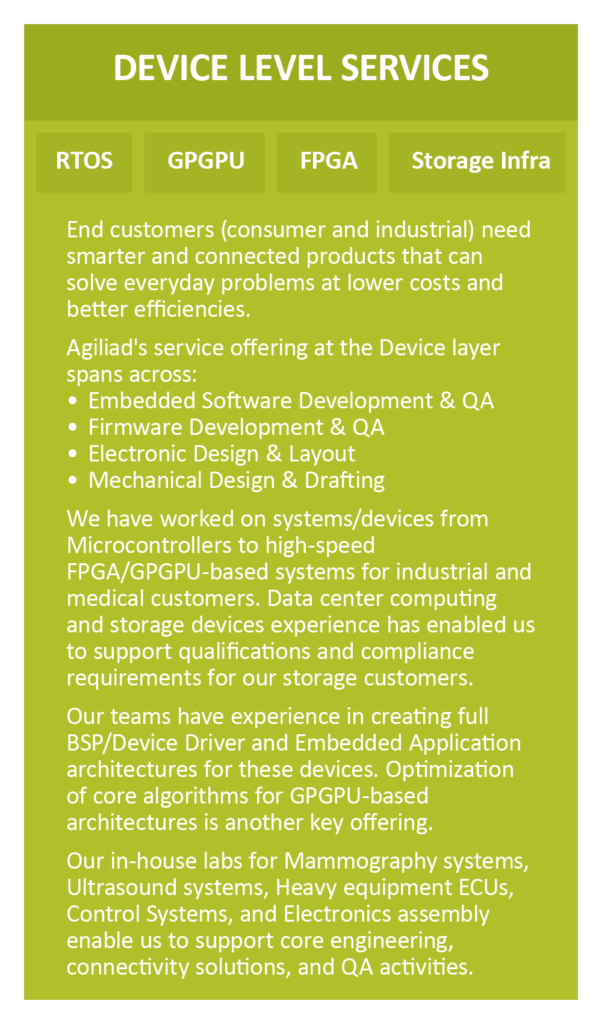

Device Level Services

Our in-house labs for Mammography systems, Ultrasound systems, Heavy equipment ECUs, Electronics Assembly fuel our pursuit of keeping up with the ever-evolving technologies. We have dedicated Hardware design and Mechanical design teams to support our customer's needs.

Accelerated Hardware systems, Deep Learning, IoT, Computer Vision, IoT are transforming the way products are designed. End customers need smarter, connected products that can solve everyday problems at lesser cost and better efficiencies.

Our Hardware, Software and IoT Technology practice, along with our deep domain expertise in embedded systems and connectivity, is supporting clients in accelerating their transformation.

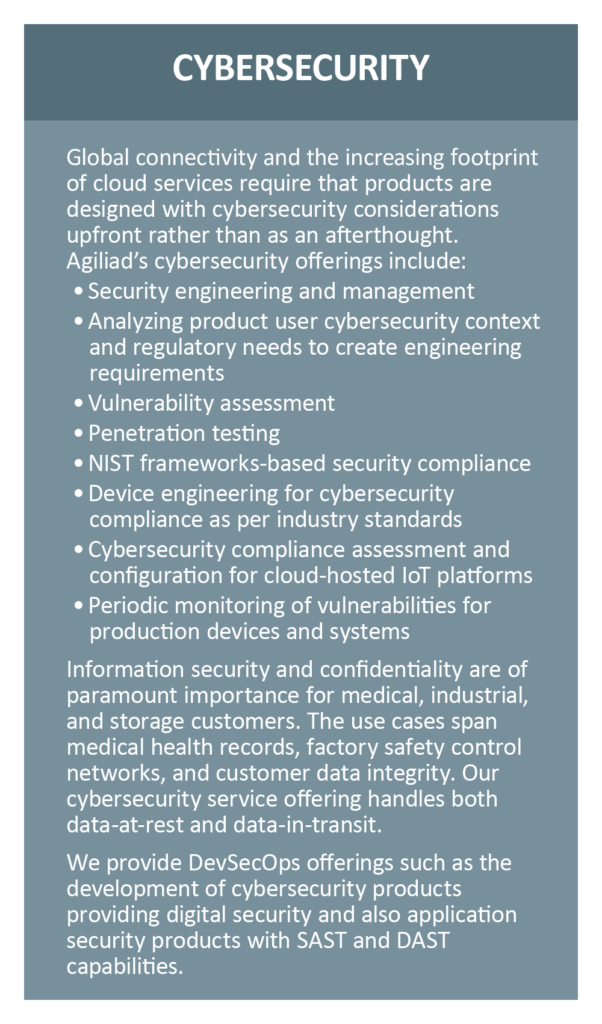

Cybersecurity

Security engineering & management

Vulnerability assessment

Penetration Testing

NIST frameworks-based Security compliance

Agiliad has been working for medical, industrial and storage customers where information security and confidentiality is of paramount important. Our cybersecurity service offering handles both data-at-rest and data-in-transit. These span use cases like medical health records, factory safety control networks, and customer data integrity.

Our capabilities and services across the product lifecycle drive our value proposition

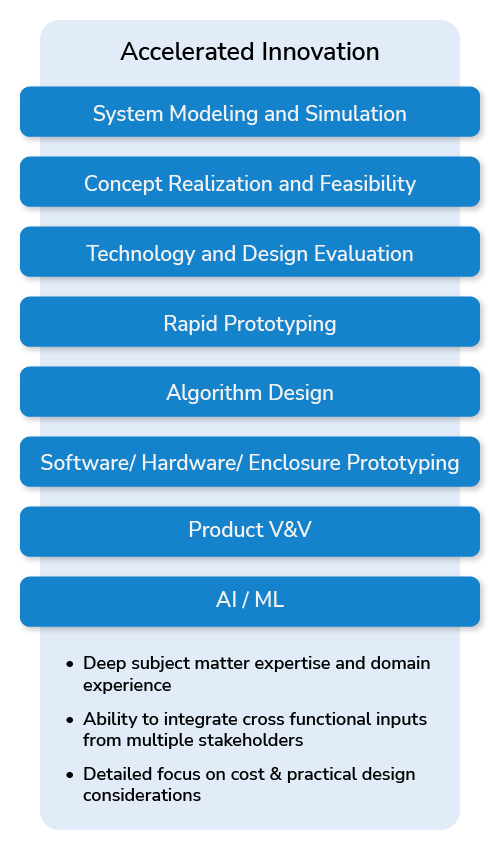

Accelerated Innovation

System Modeling and Simulation

Concept Realization and Feasibility

Technology and Design Evaluation

Rapid Prototyping

Algorithm Design

Software/ Hardware/ Enclosure

Prototyping

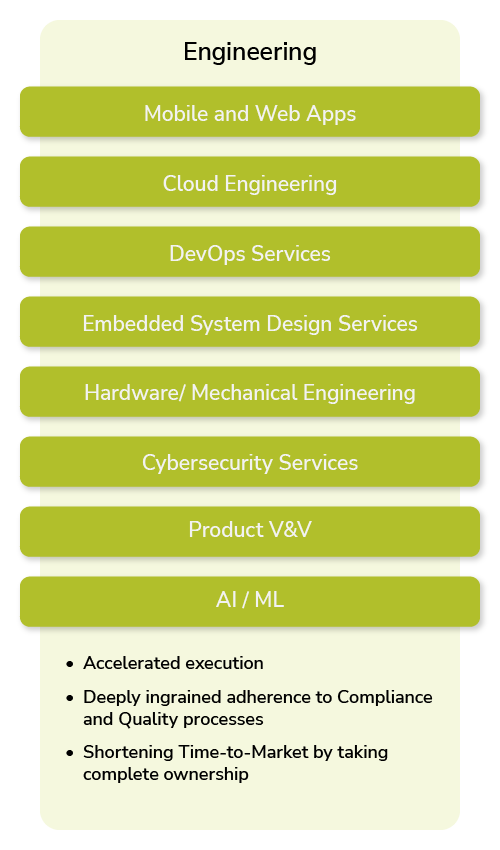

Product Engineering

Mobile and Web Apps

Cloud Applications

DevOps Services

Embedded System Design

Services

Hardware/ Mechanical Engineering

System Test and Verification

Post - Production

Product Sustenance &

Maintenance

Application and Infra Monitoring

Product Portfolio Rationalization

Self Healing Solutions

Product Obsolescence Management

Manageability Solution

Deep subject matter expertise and domain experience

Ability to integrate cross functional inputs from multiple stakeholders

Detailed focus on cost & practical design considerations

Our customers turn to Agiliad for our expertise and quick turn around for solution evaluation, feasibility checks and converting initial conceptual ideas into actual implementations.

Our range of value offerings from Hardware/ Mechanical Design to Native/ Web/ Mobile Apps gives us the edge to create quick solutions while keeping an eye for innovation and uniqueness in the solution offering.

Accelerated Innovation

System Modeling and Simulation

Concept Realization and Feasibility

Technology and Design Evaluation

Rapid Prototyping

Algorithm Design

Software/ Hardware/ Enclosure

Prototyping

Product Engineering

Mobile and Web Apps

Cloud Applications

DevOps Services

Embedded System Design

Services

Hardware/ Mechanical Engineering

System Test and Verification

Post - Production

Product Sustenance &

Maintenance

Application and Infra Monitoring

Product Portfolio Rationalization

Self Healing Solutions

Product Obsolescence Management

Manageability Solution

Accelerated execution

Deeply ingrained adherence to Compliance and Quality processes

Shortening Time-to-Market by taking complete ownership

Product Engineering at Agiliad is the key driver and the core of our service offerings. Industry trends are demanding agile product development across the stack with shorter time to market.

We bring together the technology, skills and operating efficiencies required to design, architect, develop and manage your product lifecycle – delivering efficiencies, speed to market, innovation and differentiation in competitive markets.

Accelerated Innovation

System Modeling and Simulation

Concept Realization and Feasibility

Technology and Design Evaluation

Rapid Prototyping

Algorithm Design

Software/ Hardware/ Enclosure

Prototyping

Product Engineering

Mobile and Web Apps

Cloud Applications

DevOps Services

Embedded System Design

Services

Hardware/ Mechanical Engineering

System Test and Verification

Post - Production

Product Sustenance &

Maintenance

Application and Infra Monitoring

Product Portfolio Rationalization

Self Healing Solutions

Product Obsolescence Management

Manageability Solution

Extensive experience with SLA definitions and compliance

Focus on end-customer experience, quick turnaround

End-to-end ownership, integrated view of product and support

Agiliad supports customers from concept to end-of-product lifecycle by provided sustenance, maintenance and product obsolescence management services. Our team of engineers provide 24x7 on call support for critical field issues.

Agiliad has executed projects that take a legacy product architecture and revamp it to support modern technology stacks successfully.

Accelerated Innovation

System Modeling & Simulation

Concept Realization & Feasibility

Technology & Design Evaluation

Rapid Prototyping

Algorithm Design

Software/ Hardware/ Enclosure

Prototyping

Product Engineering

Mobile & Web Apps

Cloud Applications

DevOps Services

Embedded System Design

Services

Hardware/ Mechanical Engineering

System Test & Verification

Post - Production

Product Sustenance &

Maintenance

Application and Infra Monitoring

Product Portfolio Rationalization

Self Healing Solutions

Product Obsolescence Management

Manageability Solution

Deep subject matter expertise & domain experience

Ability to integrate cross-functional inputs from multiple stakeholders

Detailed focus on cost & practical design considerations

Our customers turn to Agiliad for our expertise and quick turn around for solution evaluation, feasibility checks and converting initial conceptual ideas into actual implementations.

Our range of value offerings from Hardware/Mechanical Design to Native/Web/ Mobile Apps gives us the edge to create quick solutions while keeping an eye on innovation and uniqueness in the solution offering.

Accelerated Innovation

Concept Realization & Feasibility

Technology & Design Evaluation

Rapid Prototyping

Algorithm Design

Software/ Hardware/ Enclosure

Prototyping

System Modeling & Simulation

Product Engineering

Mobile & Web Apps

Cloud Applications

DevOps Services

Embedded System Design

Services

Hardware/ Mechanical Engineering

System Test & Verification

Post - Production

L1/L2 Product Support Services

Product Sustenance &

Maintenance

On call 24x7 team support

Product Portfolio Rationalization

Product Obsolescence Management

Component EoL Treacking

Accelerated execution

Deeply ingrained adherence to Compliance and Quality processes

Shortening Time-to-Market by taking complete ownership

Product Engineering @ Agiliad is the key driver and the core of our service offerings. Industry trends are demanding agile product development across the stack with a shorter time to market.

We bring together the technology, skills and operating efficiencies required to design, architect, develop and manage your product lifecycle – delivering efficiencies, speed to market, innovation and differentiation in competitive markets.

Product Engineering

Embedded System Design

Services

Mobile & Web Apps

DevOps Services

Cloud Applications

Hardware/ Mechanical Engineering

System Modeling & Simulation

Post - Production

Product Sustenance and Maintenance

Application and Infra Monitoring

Product Portfolio Rationalization

Self Healing Solutions

Product Obsolescence Management

Manageability Solution

Extensive experience with SLA definitions and compliance

Focus on End Customer Experience, quick turnaround

End to End Ownership, integrated view of product and support

Agiliad supports customers from concept to end-of-product lifecycle by providing sustenance, maintenance, and product obsolescence management services. Our team of engineers provides 24x7 on-call support for critical field issues.

Agiliad has executed projects that take a legacy product architecture and revamp it to support modern technology stacks successfully.

Accelerated Innovation

System Modeling & Simulation

Concept Realization & Feasibility

Technology & Design Evaluation

Rapid Prototyping

Algorithm Design

Software/ Hardware/ Enclosure

Prototyping

Product Engineering

Mobile & Web Apps

Cloud Applications

DevOps Services

Embedded System Design

Services

Hardware/ Mechanical Engineering

System Test & Verification

Post - Production

Product Sustenance &

Maintenance

Application and Infra Monitoring

Product Portfolio Rationalization

Self Healing Solutions

Product Obsolescence Management

Manageability Solution

Deep subject matter expertise & domain experience

Ability to integrate cross-functional inputs from multiple stakeholders

Detailed focus on cost & practical design considerations

Our customers turn to Agiliad for our expertise and quick turn around for solution evaluation, feasibility checks and converting initial conceptual ideas into actual implementations.

Our range of value offerings from Hardware/Mechanical Design to Native/Web/ Mobile Apps gives us the edge to create quick solutions while keeping an eye on innovation and uniqueness in the solution offering.

Accelerated Innovation

Concept Realization & Feasibility

Technology & Design Evaluation

Rapid Prototyping

Algorithm Design

Software/ Hardware/ Enclosure

Prototyping

System Modeling & Simulation

Product Engineering

Mobile & Web Apps

Cloud Applications

DevOps Services

Embedded System Design

Services

Hardware/ Mechanical Engineering

System Test & Verification

Post - Production

L1/L2 Product Support Services

Product Sustenance &

Maintenance

On call 24x7 team support

Product Portfolio Rationalization

Product Obsolescence Management

Component EoL Treacking

Accelerated execution

Deeply ingrained adherence to Compliance and Quality processes

Shortening Time-to-Market by taking complete ownership

Product Engineering @ Agiliad is the key driver and the core of our service offerings. Industry trends are demanding agile product development across the stack with a shorter time to market.

We bring together the technology, skills and operating efficiencies required to design, architect, develop and manage your product lifecycle – delivering efficiencies, speed to market, innovation and differentiation in competitive markets.

Product Engineering

Embedded System Design

Services

Mobile & Web Apps

DevOps Services

Cloud Applications

Hardware/ Mechanical Engineering

System Modeling & Simulation

Post - Production

Product Sustenance and Maintenance

Application and Infra Monitoring

Product Portfolio Rationalization

Self Healing Solutions

Product Obsolescence Management

Manageability Solution

Extensive experience with SLA definitions and compliance

Focus on End Customer Experience, quick turnaround

End to End Ownership, integrated view of product and support

Agiliad supports customers from concept to end-of-product lifecycle by providing sustenance, maintenance, and product obsolescence management services. Our team of engineers provides 24x7 on-call support for critical field issues.

Agiliad has executed projects that take a legacy product architecture and revamp it to support modern technology stacks successfully.

Insights

High Performance Computing in Heathcare

High Performance Computing or referred to as “Supercomputing” refers to the practice of aggregating computing power in a way that delivers much higher performance than one could get out of a typical desktop computer or workstation in order to solve large problems in Science, Engineering and Business

Deployment Engineering in IaC way

Deployment engineering is always thought of as safe deployment of one or more releases into the production environment in a programmable automation way and deliver value to customers. Deployments have now gone beyond installing and upgrading the applications to production environment. In the era of serverless computing...

Artificial Intelligence in Healthcare

The Healthcare industry, although has been late in adopting Artificial Intelligence (AI), has witnessed a transformative impact because of AI in recent years; and even more, during the COVID-19 pandemic...

Plugin Based

Architecture

A plugin is a piece of software that acts as an add-on or extension to the main program and gives an additional capability to the main program. It helps extend the core system by adding more features while keeping the core system capabilities separate from the add-on capabilities.

OPC-UA based SCADA Platform

OPC-UA provides a SOA (Service Oriented Architecture) framework for M2M communication and enterprise level IoT.

In addition to supporting basic telemetry data from devices, OPC-UA also supports events / alarms, method calls...

Our Impact

Our journey began in year 2011 when we set out to build a next generation of engineering and R&D services company designed from the grounds up to help IP companies succeed in rapidly changing environment. We decided to embody three fundamental trends that were transforming the R&D market then – products must integrate and coexist with platforms (breadth), IP becoming increasingly componentized (collaboration) and the next wave of growth coming from connectivity solutions (chip to Cloud capabilities). By design, we focused on collaborative innovation, engineering, high impact small teams and execution intensity as our core belief.

This mix with team of product engineering industry veterans as well as innovative engineers, gave us an unprecedented ability to deliver and build complex products for some of the world’s leading companies and innovators. We strongly believe engineering excellence and delivery are core to product engineering services business. Investment in infrastructure, engineering labs, delivery processes aligned to regulatory and quality needs of our customers, and micro-verticals are foundation to our service offerings.

Hiring talent for their strengths (technical, architects, domain experts, program management), encouraging a learning culture of expert leading experts, investment in skill development platforms and training our customers helped us in building high-performance engineering teams with strong product delivery culture. Our work remains true to the founding spirit of agility and sincere efforts. We take pride and drive huge satisfaction working with customer’s engineering teams in building elegant products for global market addressing society’s challenges.

Today we sincerely thank our customers, 600+ Agiliadians and partners as we are humbly celebrating 10 years of our journey.

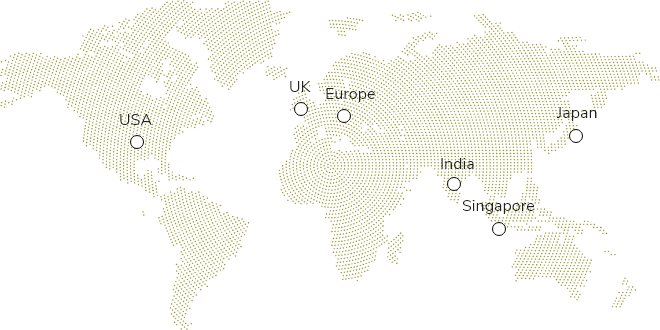

Agiliad is an Engineering and R&D Services company offering a unique combination of domain focus and a deep understanding of product platforms and diverse technologies.

We leverage the principle of collaborative innovation to help our customers realize acceleration and value not just in the development of their core products but also in their Digital transformation journey.

Key Facts:

Founded 10 years ago

Headquarters in Pune, India

Delivery centers in Pune, Noida, Mumbai, Peoria

Sales offices in Singapore, Tokyo, Boulder, Boston, Peoria

- Collaborative Innovation

- Flexible Business Model

- High Impact Small Team

- Collaborative Innovation

- Flexible Business Model

- High Impact Small Team

Services across the Product Lifecycle

Our Impact

We are proud of the impact we have made over the years – for our customers, our communities, and our team.

Our Impact

We are proud of the impact we continue to make – for our customers, our communities, and our team.

Our Impact

We are proud of the impact we have made over the years – for our customers, our communities, and our team.

Our Impact

We are proud of the impact we have made over the years – for our customers, our communities, and our team.

Improving women’s health outcomes

We have helped create IoT driven digital health platforms for cancer diagnosis and treatment. With our processes tightly integrated to those of our customers, our work in connectivity, quality, and AI/ML have led to better patient outcomes. Our focus in this area extends to supporting local non profit organizations focused on women’s health and within our own team supporting women’s careers resulting in an industry leading 41% female engineer ratio.

Advancing CT X Ray solutions

As the COVID-19 pandemic began, our team brought to bear our extensive experience in CT systems development and 3D rendering algorithms to help our customer deploy enhancements to their systems. Our engineers worked at hospitals in the epicenter of the pandemic to get improved COVID specific imaging to doctors and save lives. We also work closely with organizations focused on bringing low cost CT solutions to underserved communities globally.

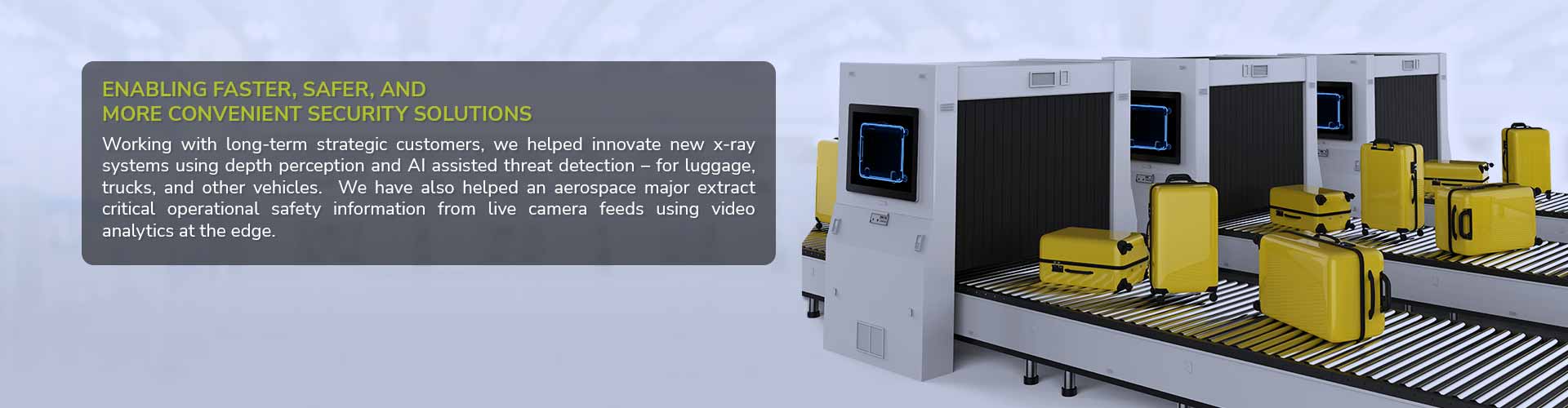

Enabling Faster, Safer, and more Convenient Security solutions

Working with long-term strategic customers, we helped innovate new x-ray systems using depth perception and AI assisted threat detection – for luggage, trucks, and other vehicles. We have also helped an aerospace major extract critical operational safety information from live camera feeds using video analytics at the edge.

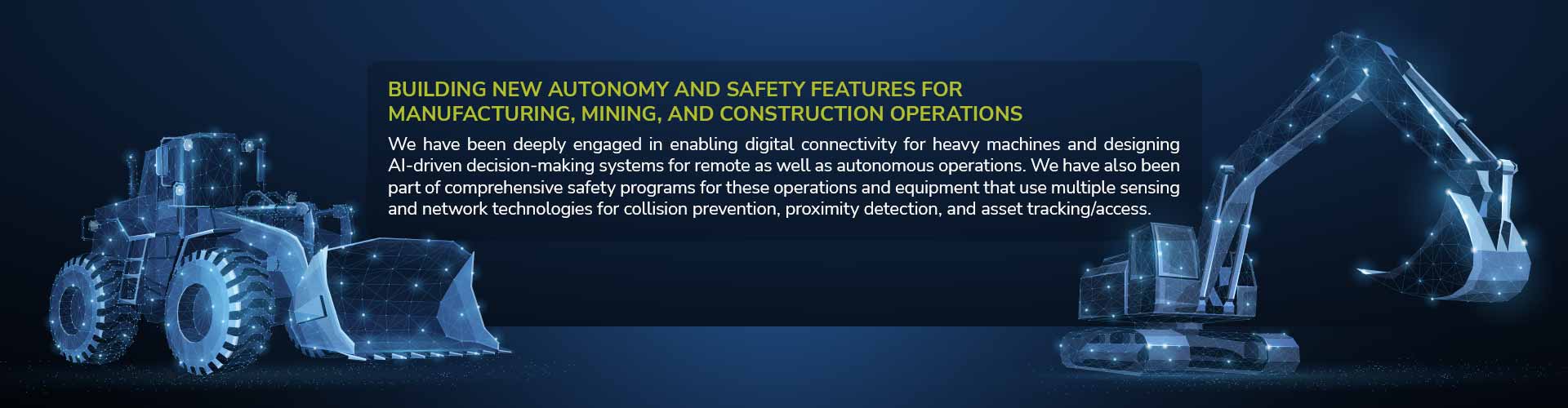

Building new autonomy and safety features for manufacturing, mining, and construction operations

We have been deeply engaged in enabling digital connectivity for heavy machines and designing AI-driven decision-making systems for remote as well as autonomous operations. We have also been part of comprehensive safety programs for these operations and equipment that use multiple sensing and network technologies for collision prevention, proximity detection, and asset tracking/access.

Partnering in the journey from startup to enterprise

As an extension to the R&D teams of our customers, we have helped rapidly scale software engineering and customer support for start-up growth organizations in enterprise storage. These collaborations span multiple years, including post exit, resulting in consistently modernized product lines that continue to drive revenue and market value.

Facilitating acquisitions in enterprise software

We have worked with leading financial sponsors to drive the technical integration of multiple enterprise software companies as part of growth strategies. This includes the technical capability to bridge/modify disparate technology stacks, implementing DevOps, and providing flexibility and bandwidth to allow seamless customer support and unwavering focus on the market opportunity.

Ensuring legacy application customer satisfaction

By taking over – in some cases entirely – the development, support, and maintenance for previous generation or orphaned product branches, we let our enterprise solutions customers focus on their new initiatives and next generation products. This also enables the end customers of these legacy products – often SMB businesses – continue with their core business and not be forced into costly and distracting technology deployment before they are ready.

Treatment of stroke patients through neuro-stimulation device

We supported our customer in taking their research on neuro-stimulation from concept to product realization. The device is intended for treatment of stroke patients. Our team was responsible for hardware, mechanical enclosure, as well as software (embedded and mobile app). The fast tracked prototyping and realization enabled our customer to initiate clinical trials early in the cycle.